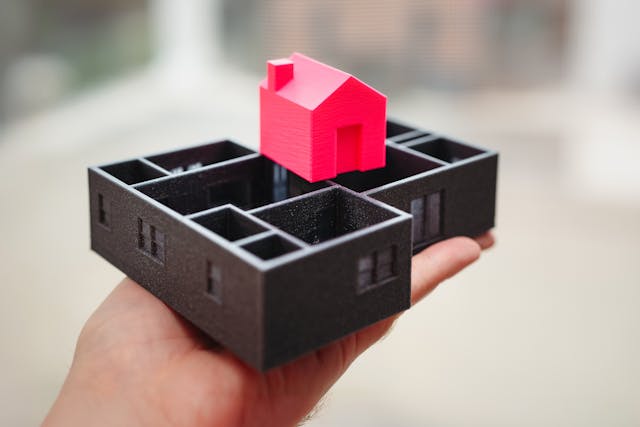

In recent years, 3D printing in construction has emerged as a groundbreaking innovation, redefining how structures are built. This technology, also known as additive manufacturing, gears towards reshaping traditional construction practices, offering a myriad of advantages that promise to streamline processes and enhance efficiency. This article explores the profound impact of 3D printing on the construction industry, elucidating why it is not just a fleeting trend but a significant evolution in the construction trades.

The Rise of 3D Printing in Construction

When we think of construction innovations, 3D printing stands at the forefront. The concept involves creating physical structures layer by layer using digital designs. This technique not only expedites the building process but also allows for incredible versatility in design. Projects that might take weeks or months to complete using traditional methods can sometimes be realized in days, if not hours.

According to a report by McKinsey, the construction industry lags behind other sectors in adopting technological advancements. However, the global shift towards sustainability and cost-efficiency has fueled the adoption of 3D printing in construction. Builders can leverage this technology to minimize material waste significantly, making the projects economically viable while remaining environmentally friendly.

Benefits of Additive Manufacturing in Construction

The benefits of integrating additive manufacturing trades into the construction sector are numerous and varied:

- Efficiency: 3D printing drastically reduces the time required to construct buildings. Fast-tracking projects leads to lower labor costs and quicker returns on investment for developers.

- Customization: Thanks to 3D modeling, designers can create highly customized buildings that appeal to diverse clients. This capability is particularly valuable in residential projects, where personalization is key.

- Reduced Material Waste: Traditional construction methods often lead to considerable waste. 3D printing constructs only what is necessary, significantly limiting excess material.

- Cost-Effectiveness: While initial investments in 3D printing may be high, the long-term savings in labor and materials make it an attractive alternative to conventional construction methods.

Examples of 3D Printing in Construction

Several pioneering projects worldwide showcase the potential of 3D printing in construction:

1. ICON and New Story’s Community in Mexico

In a mission to provide affordable housing, the collaboration between technology company ICON and nonprofit New Story has resulted in the creation of a 3D-printed community in Mexico. This innovative approach allowed the construction of homes at a fraction of the typical building cost, paving the way for future projects aimed at addressing housing shortages.

2. Apis Cor’s 3D-Printed House

Apis Cor gained fame for constructing a 3D-printed house in just 24 hours. The project showcased the efficiency of 3D printing while achieving a remarkable level of quality. This feat demonstrates how additive manufacturing trades can revolutionize residential construction and address traditional industry challenges.

The Challenges of 3D Printing in Construction

Despite its advantages, the adoption of 3D printing in construction is not without challenges. Regulatory standards and codes still very much rely on traditional construction methods, which can inhibit the widespread acceptance of this technology. Additionally, there is a learning curve for workers and builders to adapt to the use of 3D printing machines.

Furthermore, while materials used in 3D printing are evolving, the current reliance on concrete and similar substances might limit the versatility of designs. To overcome these hurdles, industry stakeholders must engage in conversations about revising regulations and increasing education and training opportunities in additive manufacturing trades.

The Future of 3D Printing in Construction

The future looks promising for 3D printing in the construction industry. As technology continues to advance, we can expect even greater innovation. The potential for integrating sustainable materials into 3D printing processes can drive an eco-friendly approach to construction. Moreover, building components could be repaired or modified rapidly through advanced digital designs.

Furthermore, as global urbanization increases, the demand for affordable housing solutions rises. 3D printing offers a feasible path to meet this demand effectively. Visionary thinkers in the construction field are already experimenting with bio-based materials and smart technologies that could further enhance the efficiency and effectiveness of construction projects.

Conclusion

In conclusion, 3D printing in construction signifies a transformative shift in the industry. Its implications for efficiency, customization, and sustainable practices set the stage for greater construction innovations. As the industry moves towards embracing this technology, we can anticipate a future where building houses and structures becomes faster, greener, and more personalized.

FAQs about 3D Printing in Construction

1. What is 3D printing in construction?

3D printing in construction involves using additive manufacturing to create structures by layering materials based on digital designs. This technology saves time and reduces waste compared to traditional construction methods.

2. How does 3D printing enhance construction innovations?

By providing increased design flexibility, reducing material waste, and cutting down on labor time, 3D printing fosters significant innovations within the construction industry.

3. Are there challenges in implementing 3D printing in construction?

Yes, challenges include regulatory hurdles, the need for skilled labor, and potential limitations in material use. However, ongoing advancements and discussions are aimed at overcoming these issues.

4. Will 3D printing replace traditional construction methods?

While it may not completely replace traditional methods, 3D printing is poised to complement and revolutionize them, offering new efficiencies and capabilities.

5. What are some future trends in 3D printing in construction?

Future trends include the use of sustainable materials, smart technologies, and expansion into more extensive multi-family housing projects as the technology matures.

References

For further reading, consider exploring: